Humanity has always been drawn to the sky. In the 1970s, hang gliding started capturing people’s interest. Flying lightweight, engineless aircraft quickly gained popularity among those inclined toward extreme sports and recreation.

Within just a decade, hang gliders became a feature at the Olympic Games. But humanity is never satisfied. A traditional hang glider only allows for soaring in air currents, which sparked the desire to enhance the capabilities of non-motorized aircraft. This led to the invention of new types of hang gliders equipped with engines.

The Architect and Pilot’s Handbook

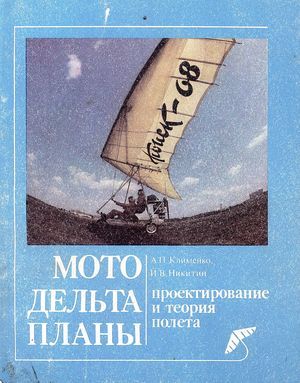

Motorized Hang Gliders: Design and Flight Theory

Motorized Hang Gliders: Design and Flight Theory

Research and experimentation in the field of hang gliders in the USSR peaked during the 1970s, paving the way for the active development of lightweight motorized aircraft in the early 1980s. The book “Motorized Hang Gliders: Design and Flight Theory” was authored by A.P. Klimenko and I.V. Nikitin—key figures in those historic events.

Despite the years that have passed, much of the information in this book remains relevant. Even today, it is considered a go-to manual for designing and piloting motorized hang gliders.

Motorized Hang Gliders

Ultralight aircraft design has evolved in two directions:

- Using aerodynamic control surfaces such as ailerons, interceptors, etc.

- Weight-shift control

Hang gliders belong to the category of weight-shift-controlled aircraft. While there have been successful attempts to design wings with control surfaces, this approach overly complicates the structure and reduces its reliability.

Don’t miss our top five movies about aviation .The carriage from an ultralight trike is sometimes used for powered paragliding. We’ve shared more about this in another article .

A new type of flying structure emerged, named the motorized hang glider (MHG). Ultralight aircraft (ULA) are classified into several groups.

Group I — ULAs that take off through the pilot’s running power, offering the following advantages:

- Lightweight build

- Ability to accommodate a low-power engine

- Suitable for takeoff from uneven surfaces

However, Group I ULAs are not suitable for transporting cargo. Additionally, they require greater physical effort from the pilot compared to Group II motorized hang gliders. The most popular engine configuration places it beneath the MHG’s wing.

Group II ULAs — These are equipped with landing gear, which can be either wheeled or float-equipped for water takeoff. Group II ULAs can carry payloads and are safer than their Group I counterparts. Pilots are securely strapped in with harnesses and protected by the structure. Takeoff and landing are also simpler in Group II designs.

During landings, it’s not uncommon for a motorized hang glider to hit the ground if its descent angle is steep. In such cases, the pilot, tilted forward, may strike their head or chest against the earth. The only way to minimize risk is for the pilot to conclude the flight by “catching” the ground with their feet.

How to choose a longboard and avoid mistakes—details on our site.

Stay warm enjoying winter sports with thermal wear. Check out our article to find the right option for you.

If you’re searching for new slopes to ski on, take a look at our feature on the Sheregesh ski resort .

Engine Configurations

Engine mounting can be categorized into several types:

On the pilot’s back.

Beneath the aircraft’s wing. A key advantage of this configuration is quick and straightforward engine installation. Furthermore, the propeller is positioned far from the pilot, enhancing safety and comfort. Internationally, motorized hang gliders with this configuration are the most popular and are mass-produced.

On a mast. This configuration was commonly used during the early days of motorized hang gliders. However, it has a drawback: the setup can sacrifice controllability and stability.

Two Engines: Either on the Wing or Supports. Aircraft with two engines did not achieve the expected success due to the complexity of its structure and lesser level of comfort compared to other types of microlights.

On a Motorized Carriage. The configuration with the pilot in a suspended position has many advantages. The motorized carriage is designed for cargo and passenger transport. It is attached to the wing of the aircraft. The landing gear, pilot seat, and other elements are also directly connected to it. Microlights with configuration No. 5 feature a simple design, affordable price, and excellent operational characteristics. They stand out among other microlights due to their reinforced frame. Disassembly and reassembly take little time, as does replacing the wing. Operating them is similar to controlling a sporty type of delta glider.

On the Wing and Supports. This is the rarest configuration. Despite their light weight, they have a significant drawback — it is impossible to control the aircraft when it banks or performs angular motion relative to the main transverse axis (pitch).

On the Fuselage. A generally ineffective configuration, which was primarily developed during the early stages of microlight aviation. It is only used when the control surface is of considerable size.

Two or More Engines on a Motorized Carriage. An analog of configuration No. 5. The main difference lies in the number of engines. Aircraft with two-engine carriages are manufactured only as experimental variants. They have some advantages over No. 5 and other carriage analogs: it is possible to balance and fly even if only one engine is operational.

Learn more about how to overcome the fear of heights on the page dedicated to acrophobia.

For those interested in learning parkour, check out our article on this new extreme sport.

Motorized Carriage Designs

Cable-Stayed

A lightweight motorized carriage that folds quickly and occupies minimal storage space. An example model is the microlight “Cosmos”. Disadvantages — less durable and reliable compared to other designs.

Panel Frame

Advantages: minimal number of supporting elements. Slightly heavier than cable-stayed designs, but its manufacturing and operational qualities are on par with the cable-stayed design. It breaks down less frequently, is highly durable and reliable, which proves beneficial in crash scenarios due to its ability to withstand impact stresses. It is suited for operation under harsh conditions. An example of a panel-frame microlight is the MAI-2 built by A. Rusak.

Truss Frame

Rarely used despite its high durability. Moreover, if one of the support elements fails, the entire system remains functional. Disadvantages of this design include numerous connecting components and the inability to fold it.

Beam

The most complex of all existing systems. It features a hollow beam with fiberglass cladding. It has minimal aerodynamic drag. However, its inability to fold makes transportation cumbersome. An example of a beam-frame microlight is the T-4, based on the “Slavutich-Sport” sports delta glider.

Delta Trikes

This type of aircraft features a body, wheel-based, ski, or float landing gear, an engine with a propeller, and a control wing (similar to a delta glider but with a larger area). The maximum takeoff weight of a delta trike must not exceed 495 kg for land takeoffs and 500 kg for water takeoffs (according to the classification of the International Aeronautical Federation).

This type of aircraft features a body, wheel-based, ski, or float landing gear, an engine with a propeller, and a control wing (similar to a delta glider but with a larger area). The maximum takeoff weight of a delta trike must not exceed 495 kg for land takeoffs and 500 kg for water takeoffs (according to the classification of the International Aeronautical Federation).

Most delta trikes are equipped with tricycle landing gear, which can be replaced with skis during the winter. If flights are intended to take off from water, the delta trike is fitted with floats. Occasionally, the aircraft may have a boat-shaped hull in place of a module. This version is intended exclusively for water takeoffs.

The wing of a delta trike is composed of a duralumin frame divided by steel cables and covered with soft Dacron fabric. It is mounted to the module (motorized carriage) via a hinge.

Ski Resort Logoysk - the most famous winter resort in Belarus.

Remember what an azimuth is? Here you can read how to use a compass for proper orientation.

A delta trike provides pilots with more opportunities, as they are not limited to flying in air currents but depend instead on the volume of the fuel tank and the fuel available. Delta trikes can operate in various weather conditions. Their advantages include:

- Light weight in assembled form;

- Easy assembly and disassembly;

- Convenient operation and maintenance;

- Versatility (usable as a glider or aerosled);

- High reliability;

- Low susceptibility to wind speed and direction.

The aerodynamic qualities of a delta trike are lower compared to a delta glider. However, in the event of an engine failure, the pilot of a delta trike can easily glide safely to the ground using its “wing.”

For takeoff, a flat, packed surface of 150 to 250 meters in length is required; for landing, a space of 100 to 150 meters. The carriage should not bounce during the takeoff run. Most flights on a delta trike occur at an altitude of 150–500 meters, although it is possible to ascend as high as 5,000 meters.

Building a Microlight by Yourself

Hang gliding in Russia has a fairly solid history. Training in hang glider flights was even offered by DOSAAF (Voluntary Society for Cooperation with the Army, Aviation, and Fleet). However, it cannot be said that hang gliding as a sport is at its peak of development. The production of motorized hang gliders with international-quality standards is almost nonexistent.

On the other hand, enthusiasts who want to learn how to fly a motorized hang glider often lack the funds to purchase a new apparatus (a new motorized hang glider costs no less than 250,000 rubles). A partial solution to this problem is the organization of regional hang gliding clubs. In these clubs, members can collectively purchase a motorized hang glider or delta trike. The costs of maintenance and service are also shared among the club participants. Additionally, everyone contributes to the upkeep of the aeroclub facilities—runways must be kept in proper condition, hangars where the equipment is stored also require maintenance, and so on. Such aeroclubs can also offer beginners training in flying motorized hang gliders.

Moreover, many enthusiasts have successfully built motorized hang gliders with their own hands. For this purpose, various components are purchased separately. Here’s an example list of the parts needed to construct a motorized hang glider on your own:

- Hang glider wing – A new one will cost from 50,000 rubles.

- Module or “cart” – A ready-to-use one costs approximately 75,000 rubles.

- Engine – Engines from small foreign cars are often used. For example, a Suzuki G13BB engine costs 50,000–60,000 rubles.

Of course, there are various other configurations. For instance, you can design and assemble the cart yourself using blueprints; in that case, you would only need to purchase the chassis and instrument panel.